I'm getting a new appreciation, and an education, about the changes of this system. Looking at

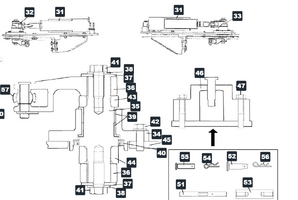

@FSH 210 Sport's pics, it's not a static position for the buckets, it's a difference in the flow pattern, and how the actuator is now a hydraulic system, vs the cables of older systems.

I can only imagine the nightmare that saltwater use adds to the equation, with all the moving parts.

@anmut, I couldn't agree more with your post. I have a feeling I'm going to be learning on the fly about these, and I'm trying to figure out how these work, at the same time I'm working on my excuse for not wanting to help my friend with his boat!