I believe the o-ring is sealing between the groove in the port and the bottom of the lip on the plug. It may also cause the rubber skirt on the plug to bulge slightly and seal against the wall of the port.

I think putting something into the gap between the rubber skirt and the cleanout plug will cause the skirt to rub as the plug is installed.

Thus far, it looks like many thanks are in order for

@TeenGee discovering another fix for water entry.

If there's a cleanout drain (or drainS) on your cleanout tray, and you have a model where they have the molded "gutters" for the cleanout tray area, I'd say you have the absolute best design, with the addition of the O-rings

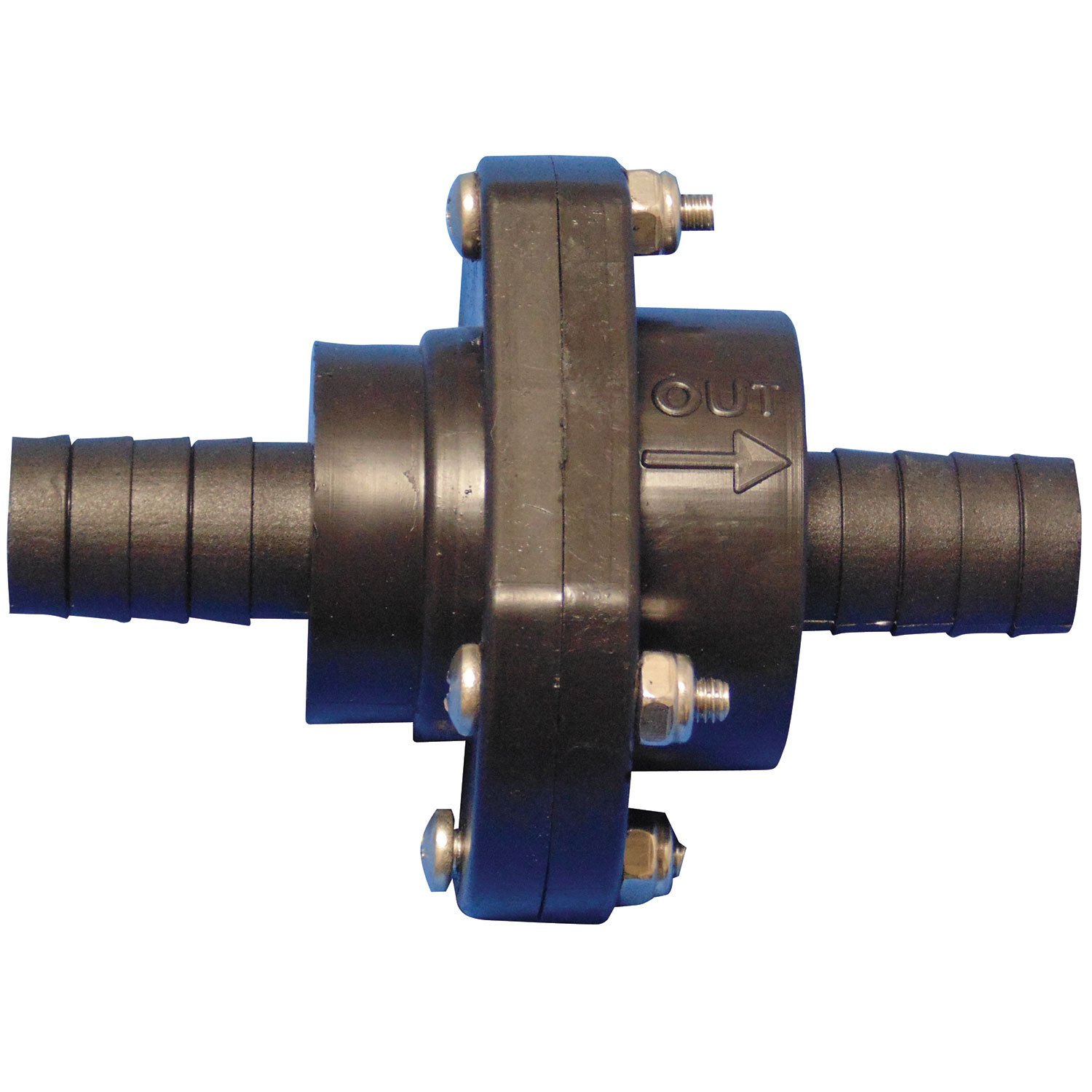

@TeenGee found. I'd still add a check valve to the cleanout tray drains to allow any water to escape, while stopping entry that occurs when coming off plane and rushing up the drain tube. This would seem to be the only way left to get water in the tubes anymore, if you've added the O-rings. The theory that any water whatsoever comes over the back deck seems to have been debunked long ago with video, and I would put this in the category of old and outdated theory, but there's always the slightest possibility....

It's odd to me that the rebuild kits don't solve this issue.

@FSH 210 Sport pointed out that when new, the OEM seals were much more snug, and the issue was at least not as pronounced as when the seals got some time on them and they wore. You'd think the OEM rebuild kits would return things to the original condition, but that doesn't seem to be the case. My theory is that the cleanout plug ears/tabs/wings or whatever you want to call them, simply wear with continued use, and no longer sit as low in the tube.

@FSH 210 Sport also pointed out that the cleanout plug metal is of a softer makeup, which makes sense. You wouldn't want the fitting that's embedded in the fiberglass at the bottom to be the metal that wore, as that would be a nightmare and quite a spendy fix to replace those, so the cleanout plugs would be the eventual wear item.

At $170-ish EACH, that's still a tough pill to swallow, so hats off to

@TeenGee for this find. A few bucks for some O-rings, and you can extend the need to purchase those brand new cleanout plug assemblies when they've worn to their end-of-life point, and if your plugs never sealed from brand new, like mine and many others, this seems to put an end to water filling the cleanout tray area.

I have a friend who purchased a 2023 brand new this year - old inventory that simply didn't sell. I'll be telling him that if I were buying a new boat, the things I would address right off the bat would be as follows:

1 - Buy the O-rings. If you don't need them immediately, you will eventually, so have them on-hand, instead of tracking them down later

2 - Buy and install a check valve on all drains on the cleanout tray

3 - Buy/DIY a riser. His inspection hatch is flat to the cleanout tray. ANY water in the area will likely leak through. Since you'll have to reseal it, why not add the riser while you're in there, and end any water getting in that inspection hatch?

4 - DAP Seal N Peel from

@Babin Farms' suggestion, or silicone, for the entire edge of the cleanout tray.

*5 - forgot to add some lube to keep all the rubber parts from sticking and possibly STUCK in place

If you DIY the riser yourself, these 4 things will total somewhere around $100 or less, and you should have a dry cleanout tray area from jump. There's no way the dealer is going to do all of these things "under warranty", that won't cost you time, or possibly money (if you're forced to buy some of these parts so that they install them while

@Yamaha dithers), or both. Even with a detailed list, and even possibly pointing them to this forum and the threads, if they have to ask

@Yamaha if they'd cover it (which they UNDOUBTEDLY should), that process is simply not going to happen in a week, from the sounds of multiple reports, and could possibly take MONTHS of back-and-forth to get approval. IMO, spend the $100, do the work yourself, you'll know the quality of the work and the care you put into it, and you will be certain these things are ALL done.

This forum is absolutely great at coming up with solutions that can keep our members on the water more, and I appreciate all of the people who've come up with ideas and feedback to make our boats better. You guys rock!